In order to meet the diverse needs of our customers, we have a wide range of equipment, and all of our employees are working on manufacturing that can be used with peace of mind.

Here, we introduce some of our development test facilities and inspection facilities.

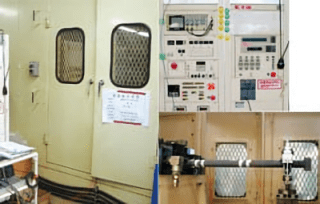

Development test facility

Impact resistance test device No. 1

- SAE waveform (flat waveform)

Base pressure 10~56MPa - JIS waveform (impulse wave)

Base pressure 10~56MPa

Peak pressure Base pressure x 150%

Impact resistance test device No. 2

- SAE waveform (flat waveform)

Base pressure 5 to 35 MPa - JIS waveform (impulse wave)

Base pressure 5 to 35 MPa

Peak pressure Base pressure x 150%

Pressure resistance test equipment

Pressurization: Max 400MPa

Vibration test equipment

Maximum static excitation force: ±11.77kN

Maximum dynamic excitation force: ±9.81kN

Excitation frequency: 0.01 to 23.3Hz

Excitation waveform: sine wave

Maximum dynamic excitation force: ±9.81kN

Excitation frequency: 0.01 to 23.3Hz

Excitation waveform: sine wave

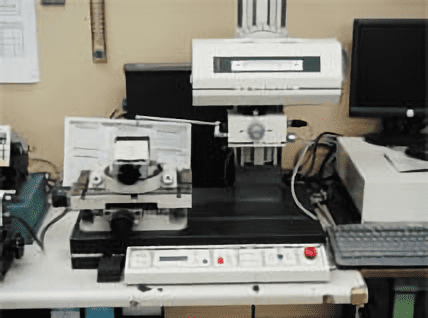

Inspection equipment

Contour/shape measuring device

CCD camera type three-dimensional measuring device

Dimension accuracy: ±0.3mm

History

Showa 22 | Started production of automobile fuel hoses |

Showa 30 | Started production of brake hoses Started production of hydraulic high pressure hoses |

48/7 | Started manufacturing pipe products |

50/4 | Started manufacturing high-pressure pipe products |

52/4 | Reinforced manufacturing facilities for hose products |

58/2 | Introduced CNC pipe bending equipment |

58/4 | Introduced high-frequency heating equipment |

59/12 | Introduced hydraulic impulse test equipment |

62/4 | Added high-frequency heating equipment |

62/8 | Enhanced CNC pipe bending equipment |

63/9 | Started mass production of high-pressure pipe products |

Heisei 3/3 | Introduced automatic TIG welding equipment |

Heisei 5/4 | Enhanced hydraulic impulse test equipment Introduced automatic TIG welding equipment Introduction of automatic processing machines |

Heisei 7/9 | Enhanced CNC pipe bending equipment Enhanced automatic TIG welding equipment |

Heisei 8/6 | Enhanced automatic TIG welding equipment |

Heisei 9/3 | Augment hose sheathing blade machine |

Heisei 13/3 | Reinforcement of hose assembly machine |

Heisei 15/1 | Expansion of NC lathe |

Heisei 15/8 | Introduced pipe three-dimensional measuring device |

Heisei 24/10 | Introduced electrostatic coating equipment |

Heisei 26 | CNC lathe update |